Although most drivers don’t give much thought to battery maintenance until it is too late, a few simple to-do tasks can keep you and your battery on time and on target.

What Are the Primary Causes of Battery Failure in Semi-Trucks?

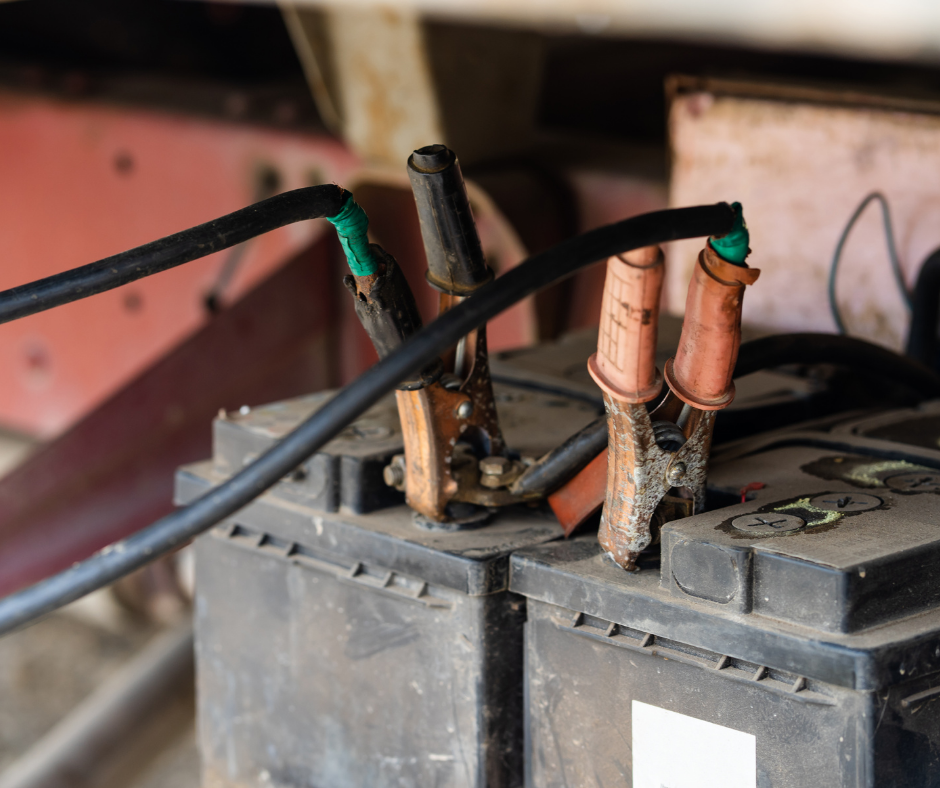

The number one reason for battery failure in your truck or bus is poor preventive maintenance (PM). Of course, you could blame things like corrosion buildup and loose cables for battery failures, but these things don’t happen if your batteries are properly maintained.

Your fleet manager will not want to hear that you missed a delivery deadline because of a dead battery. They know how simple that maintenance is; some simple steps such as these can keep you moving without missed deadlines:

- Check the cables before every trip.

- Remove corrosion. Hydrogen gas, the main ingredient in battery acid, can cause corrosion. Routine cleaning of the terminals can prevent buildup, which will cause poor battery charging.

- The more elaborate and comfortable your sleeper is, the more strain it puts on your battery. These draw on the battery’s power are known as parasitic loads. So, although you don’t want to give up any of these conveniences, you won’t have to with proper maintenance.

- Check the alternator output during routine PM. This PM component is on the Ultimate Fleet Repair (UFR) PM checklist.

- Secure the battery and check it during daily vehicle inspections. Vibration can cause poor charging and battery damage.

When Should I Replace the Battery?

Many drivers and fleets that do their own maintenance replace their truck’s battery too soon. For example, a parasitic load or malfunctioning alternator could cause a driver or fleet mechanic to replace the battery prematurely. Always check for the root of the problem before assuming that it is the battery, or you could replace the battery before it is necessary and then have to replace something else.

Once again, during routine maintenance, the professionals at UFR will check the battery and other components to ensure proper charging and less wear and tear on the vehicle’s battery.

What’s the Right Battery for My Truck?

Although most trucks and busses use a 24-volt battery, there’s more to replacing a battery than getting the correct voltage.

Two things to consider about replacement batteries are the reserve capacity (RC) and its cold-cranking amps (CCA). Fully-charged batteries retain more power to run the gadgets in your sleeper.

What’s more, an absorbed glass mat (AGM) battery offers the following benefits over a flooded-cell battery even though it might cost a little more:

- Safety

- Less maintenance

- Longer shelf life

- More CCA

When cold weather or too many appliances make your truck crank harder, you might not have the right battery. Check the owner’s manual or ask the mechanics at UFR to check out the electrical system.

Contact UFR for Battery & Other PM Items

Call the UFR professionals to schedule PM at (651) 454-8775 or use the handy contact form.